Sign In

Remember Me

Here we see the transformation of the underframe and mechanical components from a tangle of rust encrusted metal to near original condition.

Firstly all major mechanical components are removed for individual attention. One of the great advantages of the DMU concept is that the individual standardised components can be easily exchanged during maintenance, hence reducing the time the vehicle is out of service. The fact that we have 4 of everything also helps reliability in service, although this means that a lot of components needed refurbishing during the restoration!

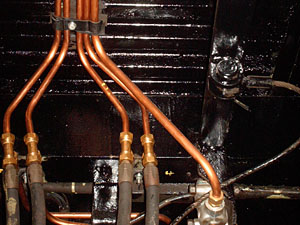

The steel air piping was replaced by copper during the rebuild. The original steel tubes were used as templates. Although copper tubing is not the original material, the unit will not be in such intensive operation on the Bo’ness branch as it was in British Railways service – problems have been experienced with this type of intermittent operation. It is hoped that the change to copper will cure previous problems in preservation service due to accumulation of rust in the air lines preventing correct operation of the EP valves.

The bogies were stripped, the wheelsets were sent for specialist tyre turning to the correct profile. MRE rebuilt the bogies, rebushing the brake rigging to original tolerances as required.

Gearboxes were inspected by a specialist contractor and rebuilding as necessary. The gearboxes are of the Epicyclic type, using a system of constantly meshed sun and planet gears, with gear selection made by a system of brake bands which wear and need occasional replacement.

The four diesel engines were rebuilt by the SRPS’s own Diesel Group. All were completely stripped and rebuilt, with parts being sourced from other preservation groups. Badly worn crankshafts on two of the engines were reground to restore the bearing surfaces.

Below we see an engine being renovated and refitted at Bo’ness by Diesel Group members. The engine is on a wooden pallet and is lifted into place by a fork lift truck. The engines are held in place by metalastic rubber & steel mounting bushes, which provide a degree of vibration isolation.