Sign In

Remember Me

The Swindon Intercity DMU vehicles are historically extremely important: The bodywork, although outwardly similar to contemporary Mk1 designs, uses a semi stressed bodyshell and was a major advance in terms of coach construction and safety on British Railways. The Swindon Intercity vehicles were thus a very important step in the development of the British Railways standard coach types.

Comparison with an ordinary Mk1 passenger coach of the same period reveals that the Swindon vehicles have no underframe truss rods – this was important to the DMU design as it allowed the full underframe area to be utilised for engines, gearboxes and other equipment.

In this respect the Swindon Intercity DMU bodyshell was a significant intermediate step between the first of the British Railways coach designs, the Mk1, and the later Mk2 series.

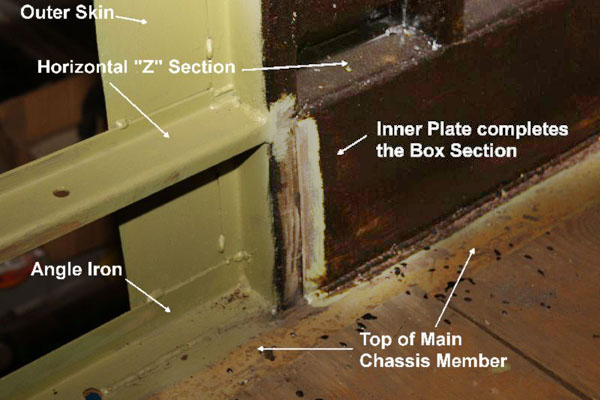

Cutting away the lower bodywork corrosion on Sc79443 – as seen in the first image – shows details of the construction techniques. Take a close look at the double skin steel forming the lower bodywork. It may not look like much, but the built up box section at the lower edge of the bodywork was a major improvement in terms of carriage design and it is no exaggeration to say that the improved structural integrity which resulted has contributed to the saving of many lives.

The Swindon DMU vehicles look outwardly similar to contemporary BR Mk.1 designs, but have a slightly different body profile and window fixing. However when we started bodywork restoration we discovered that the differences are even more fundamental.

Traditional British coach building techniques were based on a substantial chassis construction which was strengthened with an underframe of rods or welded angle sections. The body (whether steel or the earlier wooden bodies) was bolted to the chassis, but did not carry any load.

The early BR Mk.1 coach designs followed an amalgam of the best of the Big Four company practices: Construction was based on a substantial steel chassis with welded underframe trussing. The bodywork was made from welded steel hoop sections carried on outriggers, skinned with standard bodywork panels. The bodywork, however, still provided no strength to the vehicle.

Compare close up of the underside of the body to chassis joint of a standard Mk1 vehicle with the Box Sections shown on the two Swindon DMU photographs above and below. On the Mk1 ote that the frames (only) are joined to the chassis by outriggers. The body and chassis are effectively completely separate constructions. The underframe simply carries the body which in turn provides no strength to the chassis.

When Swindon Works first looked at the design of the early Modernisation Plan DMU vehicles (the Intercity sets for the Edinburgh – Glasgow service), they faced the challenge in the Design Brief from the British Transport Commission to dispense with the underfloor trussing. This was required to provide enough space for the underfloor power and ancillary equipment and to reduce the weight per unit length of vehicle to within the capabilities of the 150hp diesel engines then available.

Swindon’s solution was to fabricate the chassis from substantial steel frame sections. Crucially the body was solidly welded to the chassis via the box-section. This resulted in a semi-stressed skin with the bodyshell fully integral to the construction of the vehicle, allowing the trussing to be dispensed with.

Trailer First vehicle W79470 (initially allocated to Birmingham – South Wales services before joining the rest of the fleet in Scotland) was sent to the SNCF 200ton end loading testing facility at Vitry in France in April 1957 for stress testing during testing of the Swindon DMUs. The tests were successful and the report concluded that although it was not possible to determine the stresses in every single part of the body, that the general levels observed were acceptable under maximum test load.

The same body construction used in the DMUs was used by Swindon during development of the BR Mk.2 carriage prototypes. The prototype Mk 2, W13252 was in fact built on the DMU jigs. With the exception of the additional cosmetic curve under at the bottom of the Mk.2 body hiding the main chassis members, the profile of the Mk.2 coach is almost identical to the Intercity DMU vehicles.

The Swindon DMU vehicles are thus a very important stage in the development of the British railway carriage, with the greater bodyshell integrity of the construction first seen on the E&G Intercity railcars providing a substantial improvement in strength and crash-worthiness over its Mk.1 predecessors.