Sign In

Remember Me

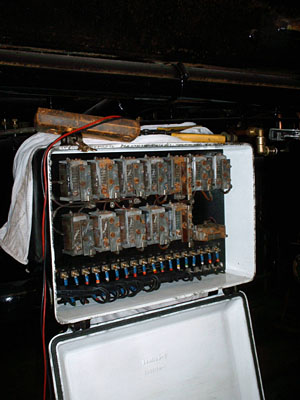

These views illustrate the work which is required to refurbish some of the (many) electrical junction boxes and relay boxes on the train. Both power cars are mechanically very similar, and as each power car has two engines, we had to refurbish 2 (or 4) examples of each of these boxes.

As can be seen, the condition of the boxes was initially very poor – The boxes had suffered from years of intensive service – and perhaps suffered even more from yet more years of lying out of service.

Due to aging seals many of the boxes had suffered from water ingress. Many were covered inside and out with alternate thick layers of paint, dirt & track rust, paint, dirt & track rust, paint, dirt & track rust like the rings of a tree, or archaeological strata, revealing the maintenance and repainting history of the unit!

In addition many of the securing studs for the electrical connections (ring tags) had broken due to over tightening and vibration in service. The requirements to restore the train to original condition “Museum Condition” extends to all components where practicable, so rather than just replace these components with modern (and cheaper!) equivalents, these were completely stripped and refurbished.

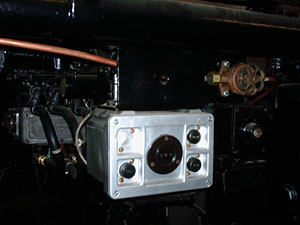

Firstly the cables and internal components were disconnected and removed. Each box was then thoroughly cleaned before being repainted. As the boxes are in general made of cast alloy, these cleaned up surprisingly well, as can be seen from the photographs.

The paxolin rails into which the studs are fitted were thoroughly cleaned. New brass electrical studs were sourced and fitted in preparation for rewiring.

New wires were pulled – each power car has a total of approximately 2000 meters (1.25 miles) of wiring. Each vehicle has about 600 individual lengths of wire, each of which have to be belled out to ensure correct connection. Wires are cut to length and wire numbers and ring tags are fitted. Note that when the wires are connected to a rail, they are fitted all from the same side in such a way as to allow the rail to be partially removed in the event of e.g. a stud breaking and needing replacement.

As part of the “Museum Condition” requirement for originality, one of the requirements was to remove a later fitted experimental “EP” (Electro Pneumatic) valve assembly from Sc51017. This was a hard decision to take as this has always been the most reliable EP valve unit on the train, but we hope that the improvements we have made to the air system in replacing the original steel piping with copper and refurbishing all the old type EP valves shall contribute to reliable operation of the systems.

The experimental EP valve assembly will be conserved for reference.